Tools

High quality tools are designed and built in house by our sister company, Abbott Tool & Die. Depending on customer requirements, NCS performs capability studies to confirm special characteristics. NCS utilizes a Zeiss O-Inspect CMM and a portable Romer Arm with laser scanning capabilities to verify parts meet design specifications.

Best Practices

At North Central, our Best Practices stand as three pillars; safety, quality, and productivity. We are OSHA compliant and pride ourselves on sound ethical operations and values. We utilize technology to be industry leaders but also recognize the value of historical best practices.

Experience

With a collective 500 plus years of experience in the toolmaking and stamping industries, it's easy to see why we're trusted by some of the leading names in Building Supplies, Automotive, and Refrigeration. Our team is committed to deliver a good product on time every time.

Tool and Die

The incorporation of Abbott Tool and Die as & North Central Stamping, gives us the unique ability to design our dies in-house. When your product doesn’t change hands halfway through the manufacturing process, it reduces error and delay to timelines. We de-bug and are production ready at kick-off.

Stamping

Our stampings go through Initial Inspection, In-process inspection and final inspection to ensure conformance. The tools are built with quality in mind using gaging and poke yoke methods.

|

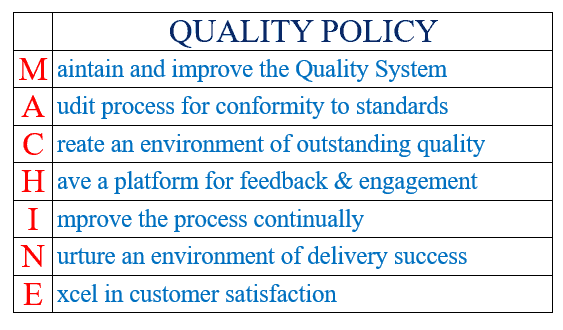

At North Central Stamping we are ISO 9001:2015 and IATF 16494:2016 certified and our goal is to build quality stampings by utilizing best practices, state of the art equipment and industry experienced tradesmen and operators. |